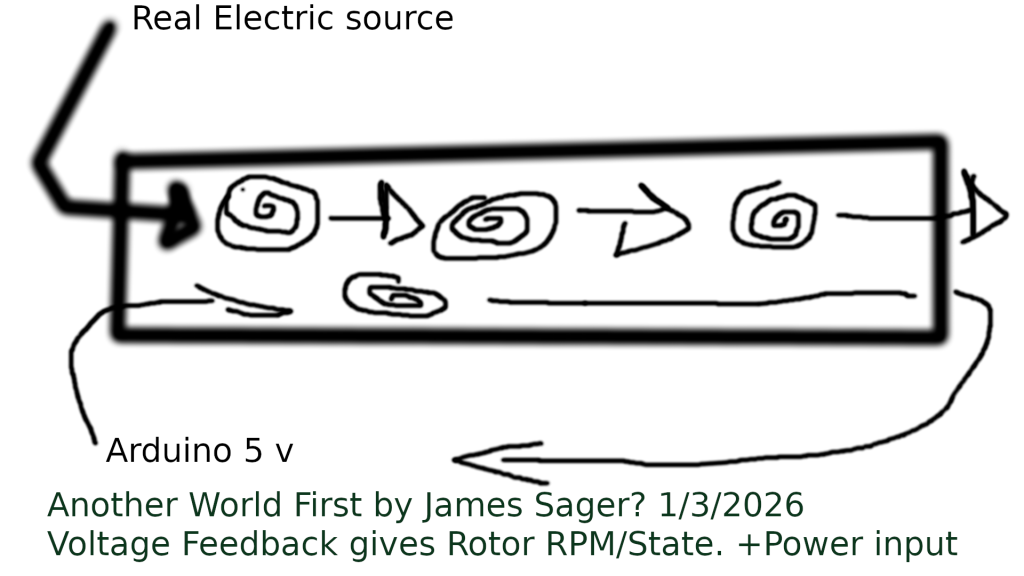

I invent world changing things from time to time… Smart Phone, LLM, Von Nuemann Probes, all me: www.techaform.com

This is an outside rim of a SRM motor that can be actively monitored and even driven forward by the monitor via Ardino, then regulated by the software.

Dual-Channel Arduino-Based SRM Control System

Overview:

A dual-channel control architecture for Switched Reluctance Motors (SRMs) that leverages a low-cost Arduino to achieve sensorless real-time rotor feedback, minimizing hardware complexity while maximizing efficiency and torque.

1. High-Power Drive Channel

- Energizes the SRM’s main stator coils to produce torque.

- Uses standard MOSFET or IGBT switches.

- Handles full motor voltage and current.

2. Low-Power Sensing Channel

- Uses auxiliary coil(s) or lightly tapped main coils.

- Induces a small voltage proportional to rotor position and speed.

- Conditioned for microcontroller input via:

- Voltage dividers

- Op-amp buffers

- RC filtering

Draws negligible current; does not affect torque.

3. Arduino / Microcontroller Control

- Reads voltage from the sensing channel via ADC inputs.

- Calculates:

- Rotor angle

- Rotational speed (RPM)

- Optional torque/load estimates

- Adjusts high-power PWM timing in real time for optimal torque and efficiency.

4. Key Advantages

- Parts Reduction: Eliminates Hall sensors, encoders, and extra isolation circuits.

- Cost Efficiency: Arduino-level controller replaces costly DSP/FPGAs.

- Scalability: Works from hobby motors to high-torque EV-sized SRMs.

- High Reliability: Sensorless design with minimal hardware → fewer points of failure.

- Energy Efficiency: Real-time feedback aligns coil energization with rotor state, reducing torque ripple and copper losses.

5. Why This Matters

- Electric Vehicles: Fewer parts, lower weight, easier maintenance.

- Aerospace / Space Systems: Robust, low-complexity, reliable.

- Rapid Prototyping: Arduino-friendly implementation allows fast iteration while maintaining precision.